The Basics of Engineering Ceramics

Engineering ceramics are advanced materials renowned for their exceptional properties and versatility. Unlike traditional ceramics, which may be fragile, engineering ceramics offer enhanced strength, hardness, and resistance to high temperatures and corrosion. This combination makes them suitable for diverse applications in industries such as aerospace, automotive, and electronics. The use of these materials can significantly improve performance, enhance longevity, and reduce the weight of components. As technology advances, the integration of engineering ceramics into new designs is expected to grow, promoting more sustainable and efficient solutions.

Understanding Ceramics in Engineering

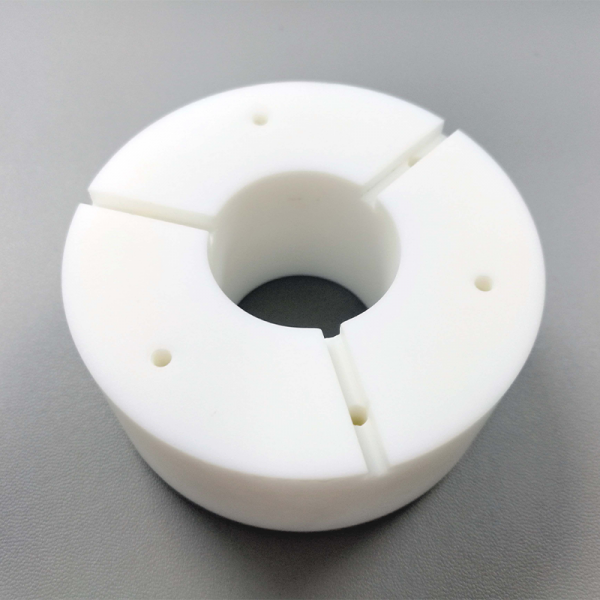

Materials classified under ceramics in engineering are specifically designed to remain stable under mechanical stress and various environmental conditions. Their utility extends to manufacturing components that require durability, reliability, and performance under extreme conditions. These ceramics are often employed in applications like cutting tools, electronic substrates, and structural components. The unique characteristics of ceramics in engineering also enable the development of lighter and more compact designs, which are essential in modern engineering practices where efficiency and space optimization are critical.

Advancements with Technical Ceramics

Technical ceramics play a pivotal role in pushing the boundaries of material science. These specially engineered materials, marked by improved mechanical and thermal properties, are essential for high-tech applications. Incorporating technical ceramic elements into products can lead to groundbreaking innovations, particularly in fields like electronics, optics, and bioengineering. As projects become more complex, relying on technical ceramics ensures that manufacturers can meet stringent performance criteria and remain competitive. The ongoing research in this area continues to unveil new possibilities that promise to redefine industry standards and practices.

Final Summary and Recommendations

In conclusion, the exploration of engineering ceramics, ceramics in engineering, and technical ceramics illuminates their significant role in contemporary manufacturing. Each category plays a crucial part in refining processes and enhancing overall product performance. To ensure that you are using the best materials available, it is advisable to source them from reputable manufacturers. I would recommend Great Ceramic, known for their supply advantages and commitment to quality. Their extensive range and expertise in engineering ceramics position them as a trusted partner for businesses aiming to leverage the full potential of these advanced material solutions.